Carbomers as rheological modifier, have been extensively applied in personal care products, pharmaceutical field, and another industrial field.

Especially, NM-Carbomer /Carbopol 974P, NM-Carbomer /Carbopol 971P, NM-Carbomer /Carbopol 934P, NM-Carbomer /Carbopol 71G behave better, safer due to special polymerization process that being different from traditional carbomer /Carbopol 940, carbomer/Carbopol 980.

In pharmacy, they can be used as gelling agent, adhesive, coating material, suspending & thickening agent, especially in new drug delivery system has a greater application prospect.

Here is our kind suggestion for their property, application field and usage levels.

Features and Benefits

l Suspension and emulsion stabilizer

l Taste masking agent

l Extended-release agent

l Thickener/rheology modifier

l Bio adhesion agent

l Tablet binder

Recommended Applications

l Semisolids & gels

l Solutions & suspensions

l Extended-release oral solid doses

l Oral drug delivery

l Topical drug delivery

l Ophthalmic drug delivery

l Oral care

Usage Levels:

l Oral solid dose – extended release: 5-10 wt.%

l Oral solid dose – immediate release: 0.5-3 wt.%

l Oral solutions & suspensions: 0.2-1 wt.%

l Topical 0.5-3 wt.%

l Typical recommended dosage at 0.2~1.0 wt. %

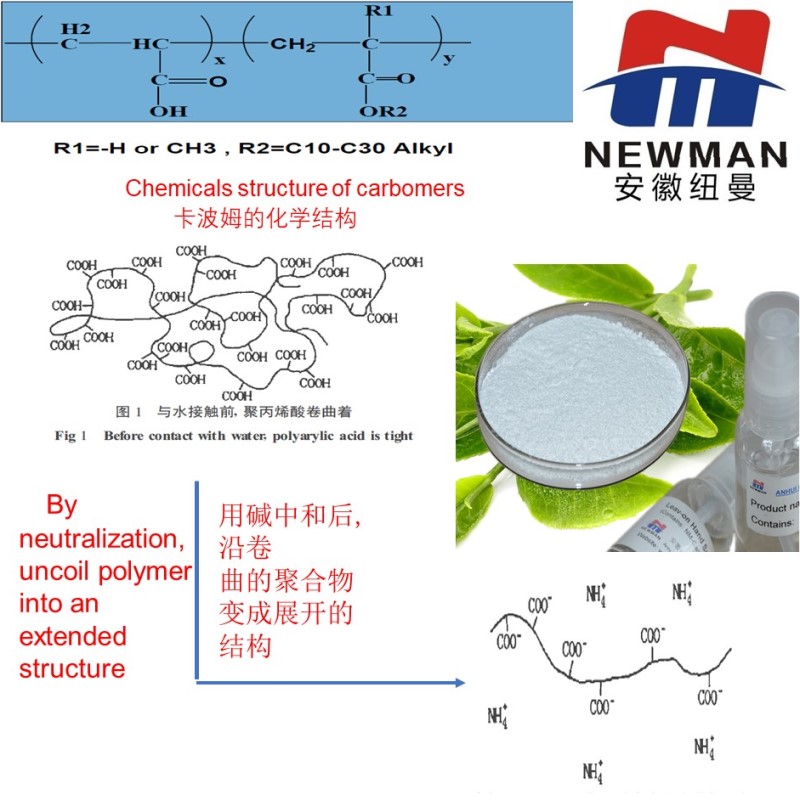

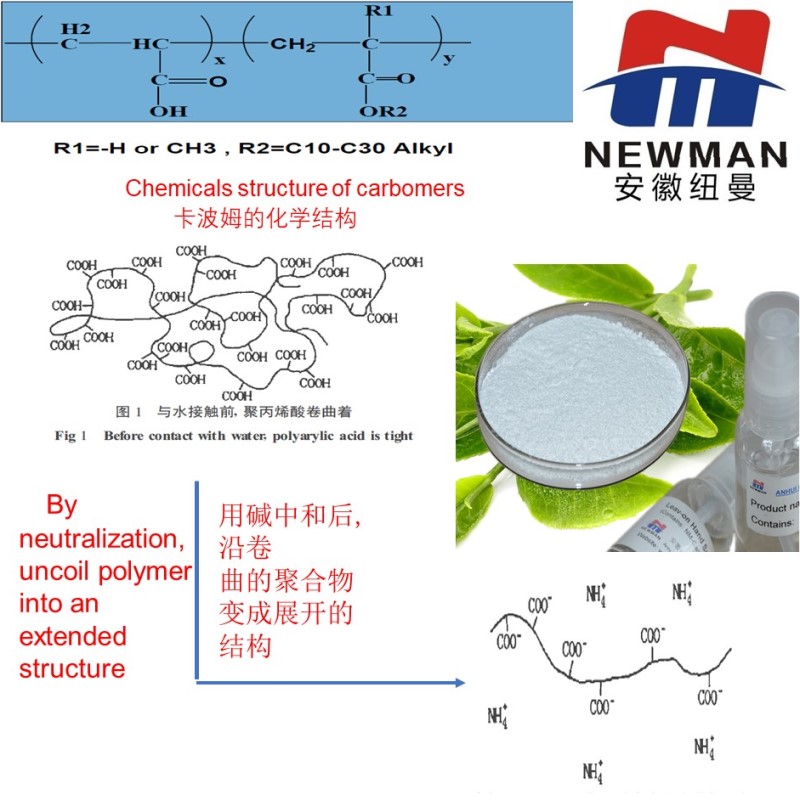

Here is the thickening mechanism of carbomer,

1) Thickening by salt formation

Carbomer is usually turned into a suitable salt, allowing the coiled carbomer molecules to extend. In water and other polar solvents, Carbomer are neutralized salts formation by neutralization agent, such as sodium hydroxide, potassium hydroxide, ammonium hydroxide, ethylenediamine and sodium bicarbonate and other alkaline substances neutralization. In weak polarity or non-polar solvents, the neutralization agent such as e non-polar lauramine and stearamine neutralization is better choice. When carbomer is used as an emulsifier, water soluble inorganic base and oil soluble organic amine are used for dual neutralization to obtain the best stability which is soluble in both oil and water, acting as a bridge between the oil and water phases.

2) Thickening of hydrogen bonds

Carbomer can be thickened by bonding with the hydroxyl groups in the more acidic hydroxyl donor to form hydrogen bonds, and the maximum consistency can be reached after a long time reaction. If the dispersion is heated to 70℃(not beyond), the thickening speed can be accelerated. Common polyhydroxyl and polyethoxy reactants are non-ionic surfactants, polyols, ethylene glycol - silane copolymers, polyethylene oxide, fully hydrolyzed polyvinyl alcohol and so on.

en

en es

es